Solution

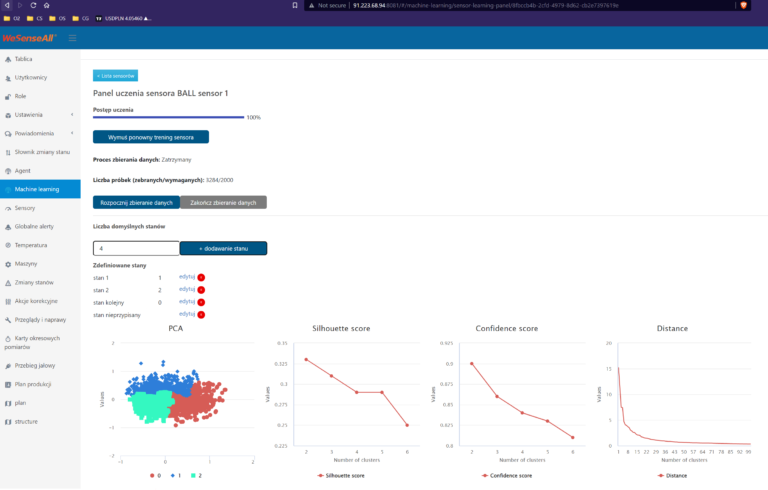

Therefore, our team began researching supervised machine learning methods to select the most effective classification models. This approach helped to narrow the scope of the potential use of regression models to determine the state of a machine in real time.

In the beginning, the data sources provided by the client had no labels and were quite small. We offered the client to integrate the system with a cloud infrastructure with all the necessary anonymous data stored in Azure DataLake (the solution was economical and allowed unlimited storage). To work with data, we used our open source library CogniPy.

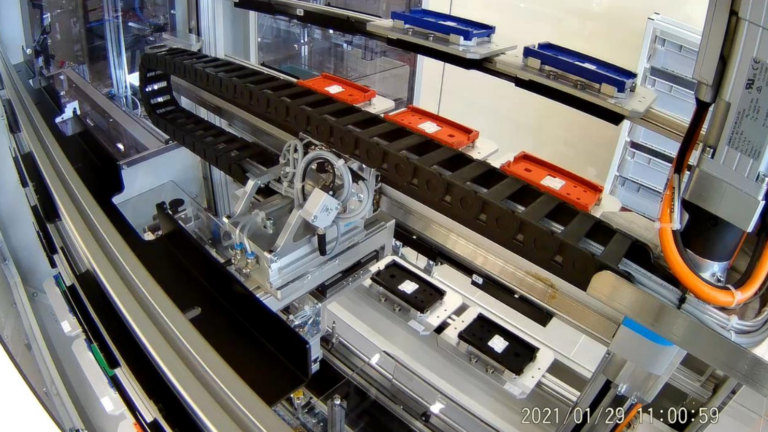

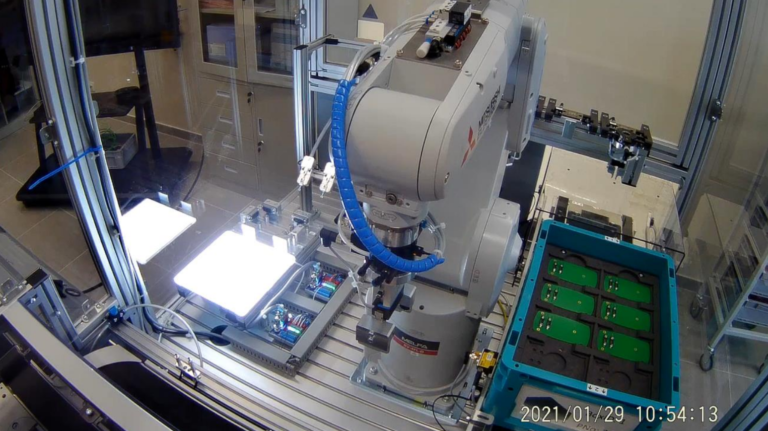

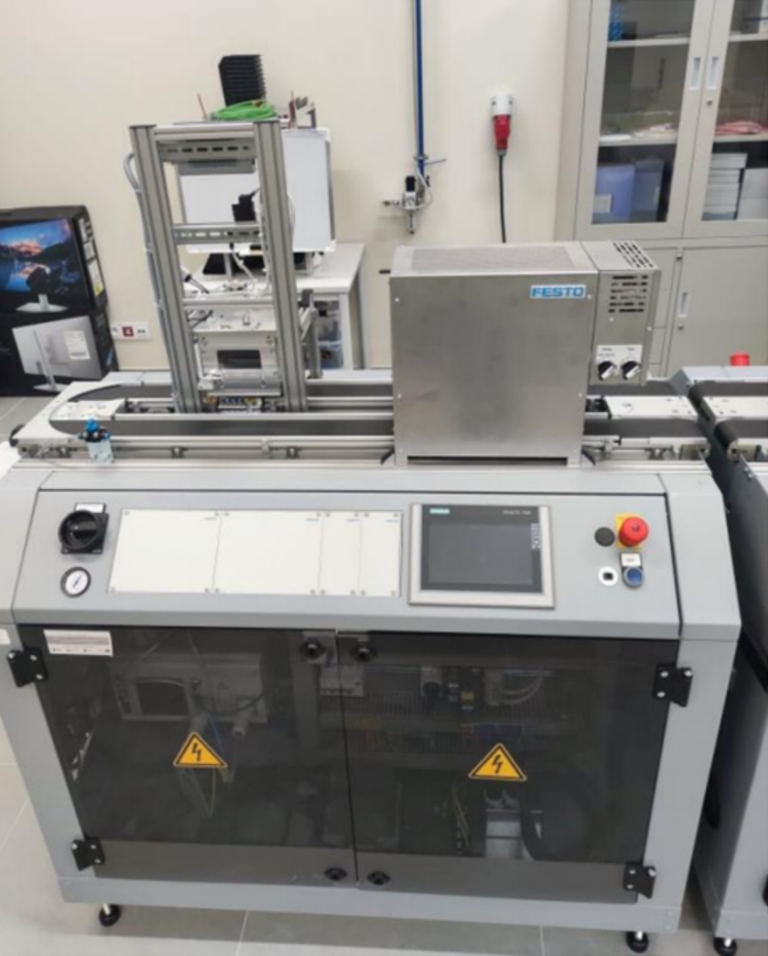

In addition, thanks to Politechnika Świętokrzyska, with whom we work closely on many other projects, we gained access to their laboratory production line to run several tests. This allowed us to collect valuable data to train and validate our models and deliver the project on time and according to the agreed requirements at the beginning.

Previously, the client worked with an LTE connection to send the latest measurements from sensors. This entailed several problems, since measurements could be delayed, some of them could not be available at all due to less network stability. In such scenarios, data was sent without confirmation that the target service had received it. When building regression models, delays and missing samples required special attention to ensure satisfactory results. Standardization and appropriate interpolation algorithms were used. In addition, the client plans to switch from LTE to 5G in the near future. The system will be implemented in such a way that it can handle a much larger data stream.

As a result, the client got an IoT solution that shows easy-to-understand state prediction parameters and does not require special skills to work with. The web app warns him about anomalies and machine states in production within 1-5 seconds. Thanks to flexible settings he can choose the notification method himself (sms, e-mail, others). It is intuitive and easy to use, with an admin panel where anyone gets access to real-time analytics (gathered data for each machine and sensor, their state and downtime period if any). Besides, one can add other people and assign them roles with different rights permission (Admin/Super Admin/Operator), change settings in accordance with the data being collected, and much more.

The client was satisfied with the result of our cooperation and is going to continue it. There are plans to launch new versions of the web application with deeper and more detailed analytics and more specific machine states on the line.